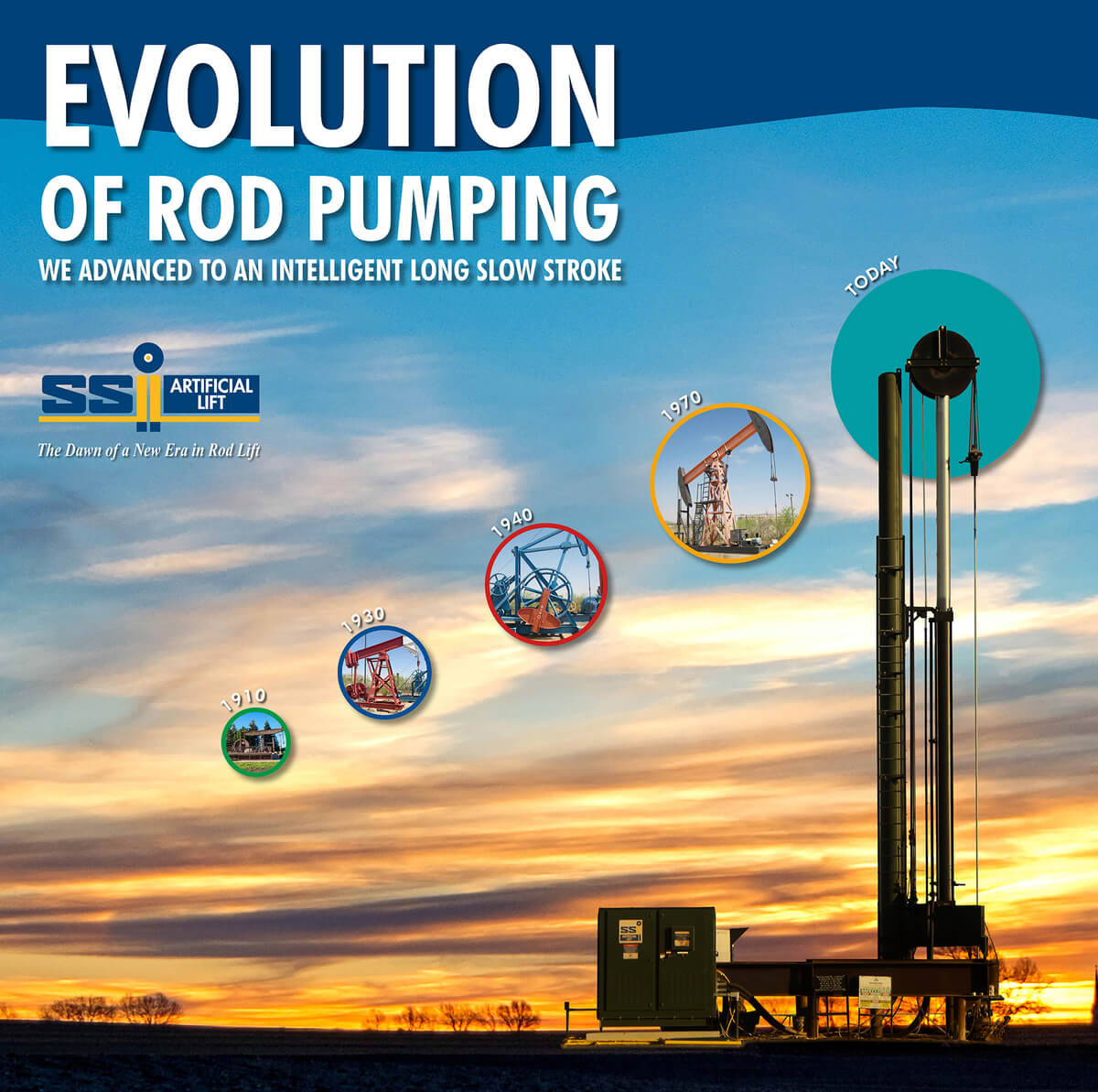

The Dawn of a New Era in Rod Lifting

Which Major Challenges Can Our Intelligent Lifting System Solve?

Prevent Fluid Pounding and Rod Buckling

SSi’s Advanced Pump Off Controller (POC) is designed to prevent fluid pounding and rod buckling while ensuring optimal pump fillage. Unlike traditional POCs, our system automatically adjusts the up and down speeds to maintain a rectangular surface card, resulting in maximum efficiency. Operators can set limits for the minimum and maximum strokes per minute (SPM) and control speed changes.

When fluid pounding or rod buckling is detected, the system reduces speed, and it increases when pump fillage improves. These parameters are fully customizable, providing precise control for enhanced well production.

Minimize Rod Hang-up and Carrier Bar Separation

Our advanced system minimizes rod hang-up and carrier bar separation, automatically adjusting speed to avoid operational issues. The unit doesn’t immediately drop to the lowest speed, allowing for a higher overall SPM.

When rod hang-up or carrier bar separation occurs, the system reduces speed and then smartly accelerates when the separation issue resolves, maintaining smooth, efficient operation.

Prevent Costly Shutdowns

SSi’s system detects abnormal increases in rod load and responds before damage occurs. If rod load exceeds the operator-defined set point, the unit reverses direction and continues pumping, allowing production to continue while downhole issues are addressed.

This feature prevents costly shutdowns and the risk of sand build-up, ensuring continuous well operation.

Reduce Rod Stress and Extend Lifespan

To reduce stress on the rod during operation, our Turn Around Load Control pauses the unit at the bottom of the stroke, allowing the rod to relax before the upstroke begins. This reduces stress on the rod, extending its lifespan. Operators can set the pause time between 0.1 to 999 seconds.

For pumped-off wells, the system distributes pauses throughout the day, avoiding lengthy shutdowns and maximizing production time.

Minimize Waste & Optimize Well Performance

SSi’s Chemical Injection Control system precisely manages the injection of chemicals, minimizing waste and optimizing well performance.

By coordinating the injection pump with the load and position within the stroke, the system ensures chemicals are applied at the right time, improving efficiency and reducing costs. Operators can fully customize the injection timing to suit their needs.

WANT MORE? wATCH OUR INTERVIEW AT PBIOS LIVE 2025 BELOW: