This case study showcases increased production and reduced overall life cost on an ESP replacement in the Permian Basin. This includes electrical usage and carbon footprint.

Written by Frederick M. Kemp IV – Riley Exploration Permian, Inc.

*Excerpts taken from the original presentation, which was presented at the Permian Basin Artificial Lift Forum Bush Convention Centre Midland, Texas 2 – 3 November 2021.

“In today’s operations, the most impactful thing we can control is our LOE, both on a CO2 metric and what hits our pocketbook. By converting to rod pump earlier, we enjoy the substantial electrical cost savings of rod pump, as well increased production from gravitational gas separation. SSi units allow us to push the envelope of what is possible on rod pump to convert wells several years earlier than originally thought possible.” – Fred Kemp, Riley Exploration Permian Inc.

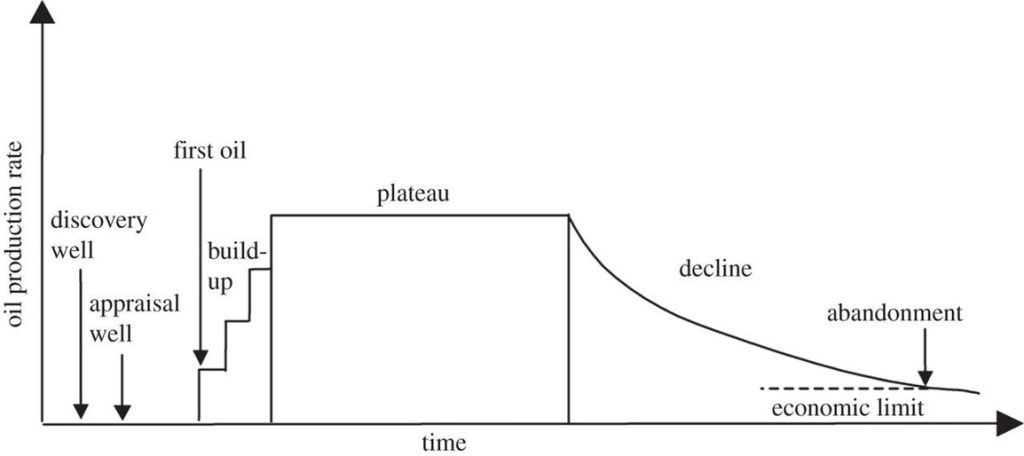

Selection of Artificial Lift in New Oil Wells.

Riley Exploration, Permian –Beaten Path 597-648 1XH

New Long Stroke, Intelligent Rod Lift Technologies’ earlier introduction decreases overall costs such as workovers and electrical consumption.

Traditionally, the Selection of the Artificial Method will have a direct bearing upon the well’s overall costs. ESP’s are commonly used for Primary Lift.

- Riley analyzed the market for Rod Lift Solutions

- Production =/> 1,000 BBls/day

- Peak Polished Rod Loads of 30,000 Lbs

- Min Load 6985 Lbs.

- 75 inch Dia. Downhole Pump

- 1 Inch Dia. Rods

- Pump Depth 4,750 Foot

- Unit Installed in Nov 2020

- Lower overall Workover Cost

- Flushby Units or Workover Rigs

- Opted for the SSi Model 400 LS-200-336

- Small Footprint – 12 Foot Maximum

- 336 inch stroke length

- Independent Up and Downstroke

- Smart Speed Logic – Auto-Optimization

- 200 Horse Power with Integral VFD

- Rod Star showed unit could reach 1000 BBls/Day @3.8 SPM (Not Maximum)

- Unit has been running at 4.1 SPM

Downhole Card – 1st Nov 2021

Full Pump Fillage at 3.8 SPM

- Total Produced Fluids with Rod Lift avg is 750 BFPD

Patented Smart Speed Logic

- Auto Optimization Every Stroke

- Long Slow Strokes allows Gravitational Gas Separation

Faster Upstroke, slower downstroke provides full pump fillage

- Uptime in excess of 99%

- Increase Longevity of Downhole equipment

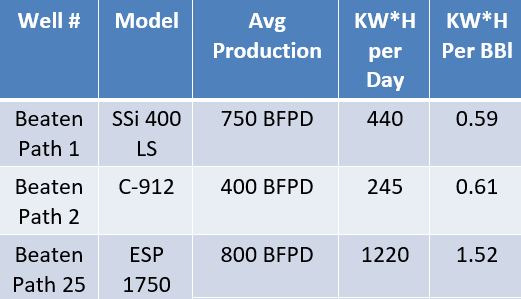

Comparison of Electrical Usage Between Systems

*The electrical consumption was measured by the Client at each well.

USA – Amount of Carbon Produced per KW*H = 0.92 Lbs

Source – IEA – International Energy Regulator

In summary, the client saved 254,587 Lbs of Carbon using the SSI Technology per barrel over one year in comparison with the ESP.

SSi Artificial Lift is shifting the paradigm within the intelligent artificial lift space. Through Auto-Optimization through our patented Smart Speed Logic II Software,

Clients are celebrating:

- Increased Production – Gravitational Gas Separation

- Reduced Costs for Installation

- Reduced Costs for Workovers

- Reduced Electrical Cost

- CO2 Emissions Reduction

For additional information and to arrange a demo tour and presentation, please contact us!